Induction heating is a commonly used process for welding metals and other materials. It involves using an electrical current to generate and induce heat (in the form of electromagnetic radiation) on the weld area, enabling it to reach temperatures higher than those that could be attained through normal welding processes. There are several different types of induction heating processes for welding , each having their own unique advantages and disadvantages. For example, one type is conduction-based induction heating which uses a direct current passing through the material being welded to produce heat. This method is generally faster and more efficient compared to others but can be difficult to control since it relies on the conductivity of the material being welded. Additionally, due to its high power requirements, this process will require large equipment with expensive maintenance costs. Another popular option is capacitive induction heating which utilizes alternating currents between two plates placed near or in contact with the material being welded in order to generate heat within it. This method offers better control over temperature since both frequencies and voltages can be adjusted as needed while also allowing for smaller equipment sizes and

Induction Heat Treatment for Welding

Essential Process for Proper Welding

Induction technology is an incredible tool for welders! It can significantly reduce the amount of time needed to heat up materials, and it can also greatly improve the quality of the weld. But if you're just starting out with induction welding, learning how to use it properly can be a challenge. Fortunately, there are some simple steps you can take to get quickly up-to-speed. Firstly, make sure your equipment is set up correctly. This involves understanding the power setting controls and selecting appropriate parameters for each type of material being welded. If you don't have prior experience with welding, it's important to read through any instructions that come with your machine carefully before beginning work. Also, keep in mind that different types of metals may require different settings and techniques to produce optimal results. Next, pay attention to pre-heating times as they vary depending on the thickness and composition of the material being used. Too much or too little pre-heat time can cause problems during welding so be sure to follow manufacturer guidelines closely! Additionally, consider using a temperature monitor or gauge when working with thicker materials so that you know exactly when

Welding is an essential skill for many professions. It's a great way to join two pieces of metal together, but it can be strenuous and time-consuming. If you're looking to speed up your welding process, induction heating may be the answer! It unlocks tremendous benefits that traditional welding techniques just can't provide. First off, induction heating is incredibly fast. The heat generated by the electrical current only affects the material you wish to weld - meaning no excess energy is wasted on other materials in its vicinity. This makes it easier and faster than ever to get those hard-to-reach areas - and all with a fraction of the effort! Additionally, because of its precision, you'll experience less distortion in your welds than before: perfect for intricate jobs! Moreover, induction heating produces an extremely strong bond between materials . Its even heat distribution allows you to quickly reach higher temperatures without worrying about hot spots or weak connections. Your welds come out stronger and more reliable every single time! Plus, with less heat being lost during the process, you won't be burning through nearly as much electricity or gas as before - saving money while

Induction heating treating services for welding is an effective way to maximise productivity! It's a great tool that can save time and money (if used correctly) by reducing the amount of energy used in the process. With its ability to heat metal parts quickly and accurately, it can help you complete projects faster than ever before. However, there are some precautions one should take when using induction heating for welding to ensure safety and efficiency. Firstly, proper safety equipment should always be worn - goggles, gloves, masks etc. Neglecting these could result in serious injury or even death. Additionally, the area where induction heating will be taking place should be well-ventilated as fumes from melting metals may cause respiratory issues if inhaled over a prolonged period of time. Moreover, it is important to use the correct materials when working with induction heating for welding. Certain metals such as aluminium do not respond well to this method so it is essential that they are avoided when choosing materials for the job at hand. Furthermore, make sure that all necessary components (like power supplies) have been tested prior to use as failure to do so

Induction heating is an innovative technology used in welding, and it can be incredibly powerful! It uses electromagnetism to heat materials instead of flames or sparks. This means that it's faster and safer than traditional welding methods, as there's no risk of fire or explosions. Plus, induction heating produces a more precise weld joint with less distortion than other techniques. However, the power of induction heating isn't just limited to welding; it can also be used for many other industrial processes. For instance, it can be employed to harden steel components for improved strength and durability and to enhance the performance of certain types of machines. In addition, it has been used to heat metals prior to extrusion or forging operations in order to increase their malleability so they can better conform when shaped into desired shapes. Moreover, induction heating is highly versatile since its application is not restricted by size or shape limitations like traditional methods are. It's also very cost-effective as it consumes less energy compared to conventional methods due to the fact that induction forces the current directly into the material being heated rather than dispersing energy throughout a large

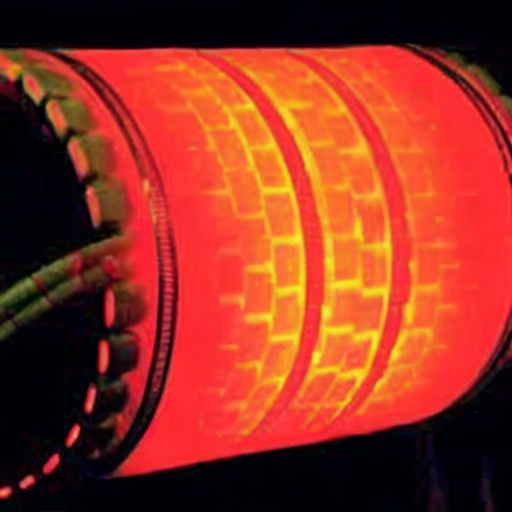

Induction heating is a revolutionary process that utilizes electromagnetic energy to heat metal objects. It has revolutionized the welding industry by providing an efficient and precise method of welding. The induction heating process begins with the generation of an alternating current in a coil, which creates a powerful magnetic field. This magnetic field induces eddy currents within the metal object, creating intense localized heat. (The higher the frequency and intensity of the electric current, the higher the temperature.) As a result, the metal object is heated to extreme temperatures – usually exceeding 2,000°F - without requiring direct contact from any external source! Moreover, induction heating offers several advantages compared to traditional welding procedures. First and foremost, it is much faster than traditional methods; for example, induction can heat certain metals up to 1,000 degrees Celsius in less than five minutes! Secondarily, it is more accurate and controllable – meaning welders are able to set exact parameters for each individual job. Finally (and perhaps most importantly) it reduces energy consumption significantly as compared with other welding techniques. In conclusion, induction heating has revolutionized welding by offering greater speed and accuracy while reducing energy consumption.