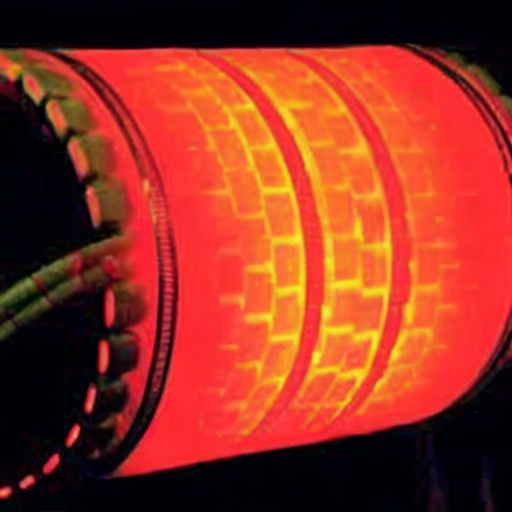

Learn How to Heat up Your Welds with Induction Technology

Induction technology is an incredible tool for welders! It can significantly reduce the amount of time needed to heat up materials, and it can also greatly improve the quality of the weld. But if you're just starting out with induction welding, learning how to use it properly can be a challenge. Fortunately, there are some simple steps you can take to get quickly up-to-speed.

Firstly, make sure your equipment is set up correctly. This involves understanding the power setting controls and selecting appropriate parameters for each type of material being welded. If you don't have prior experience with welding, it's important to read through any instructions that come with your machine carefully before beginning work. Also, keep in mind that different types of metals may require different settings and techniques to produce optimal results.

Next, pay attention to pre-heating times as they vary depending on the thickness and composition of the material being used. Too much or too little pre-heat time can cause problems during welding so be sure to follow manufacturer guidelines closely! Additionally, consider using a temperature monitor or gauge when working with thicker materials so that you know exactly when they've reached the correct temperature for welding.

Finally, remember that induction heating for welding works best when done slowly and with precision - this means taking your time as you move along each joint line and applying consistent pressure throughout the process. As a bonus tip: don't forget to use protective gear such as safety glasses or goggles when working near hot surfaces!

In conclusion, mastering induction technology isn't always easy but following these steps will help ensure successful welds every time! With patience and practice (you'll) soon become an expert at heating up materials using this powerful technique - happy welding!