Different Types of Induction Heating Processes for Welding

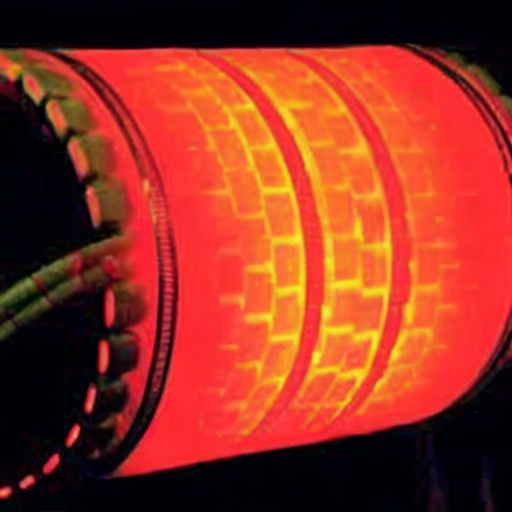

Induction heating is a commonly used process for welding metals and other materials. It involves using an electrical current to generate and induce heat (in the form of electromagnetic radiation) on the weld area, enabling it to reach temperatures higher than those that could be attained through normal welding processes. There are several different types of induction heating processes for welding, each having their own unique advantages and disadvantages.

For example, one type is conduction-based induction heating which uses a direct current passing through the material being welded to produce heat. This method is generally faster and more efficient compared to others but can be difficult to control since it relies on the conductivity of the material being welded. Additionally, due to its high power requirements, this process will require large equipment with expensive maintenance costs.

Another popular option is capacitive induction heating which utilizes alternating currents between two plates placed near or in contact with the material being welded in order to generate heat within it. This method offers better control over temperature since both frequencies and voltages can be adjusted as needed while also allowing for smaller equipment sizes and lower operational costs. However, capacitive induction heating tends to take longer than conduction-based techniques due to its slower heating rate.

Lastly, there's inductive coupling induction heating which works by transferring energy from one coil or transformer into another via magnetic fields created between them. This method allows for very precise control over temperature and requires much less energy when compared to other types of induction heating processes but has limited applications because of its reliance on magnetic fields generated by specific sources such as transformers or coils! Furthermore, inductive coupling can be costly due to its need for special components like coils or transformers in order to work correctly.

Overall, all three different types of induction heating processes have their own pros and cons that must be taken into consideration before choosing one for any given application. From fast efficiency at high power levels (conduction-based)to careful temperature control at low cost (capacitive), there's sure abscond suitable option out there no matter what your needs may be!